Ipeyinti yokuqhawula kunye neplasticizer ekuMgangatho oPhezulu ngeXabiso elungileyo le-DOP

Ukusetyenziswa

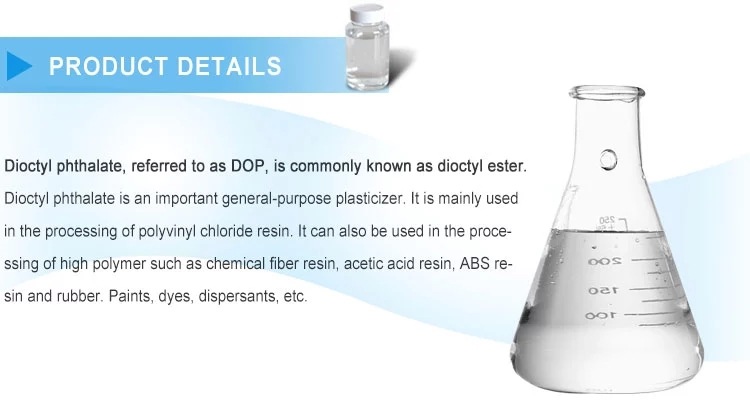

IDioctyl Phthalate (DOP)

Inombolo ye-CAS: 117-81-7

Ifomula yeMolekyuli: C24-H38-O4

| Into | Ukucaciswa |

| Inkangeleko | Ulwelo olunombala olungafihliyo olunamafutha |

| Umxholo (GC)% | 99.5 imiz |

| Ubumanzi (njenge-AC)% | 0.015 ubuninzi |

| Umbala (APHA) | Ubukhulu obungama-30 |

| Ukufuma% | Ubuninzi be-0.1 |

| Ubunzima be-20 ℃ g / mL | I-0.982-0.988 g / ml |

| Indawo yokudanyaza ℃ | 195 ubuninzi |

| Ukuphulukana nokufudumeza | Ubuninzi be-0.3 |

Umgangatho ophezulu ngexabiso elifanelekileyo le-DOP Plasticizer yokuChazwa kwePeyinti

|

Igama lesalathiso |

Isalathiso |

||

|

Kwinqanaba eliphezulu |

Ibanga lokuqala |

Imveliso efanelekileyo |

|

|

Inkangeleko |

ulwelo oluselubala, olunamafutha ngaphandle kokungcola okubonakalayo |

||

|

IChroma / (Pt-Co) # ≤ |

30 |

40 |

60 |

|

Ucoceko% ≥ |

99.5 |

99 |

99 |

|

Indawo yeFlash (ivuliwe) ≥ |

195 |

192 |

190 |

|

Ukuxinana (-20) g / cm3 |

0.982-0.988 |

||

|

Ubumanzi (njenge-phthalic acid)% ≤ |

0.01 |

0.015 |

0.03 |

|

Ukufuma% ≤ |

I-0.1 |

0.15 |

0.15 |

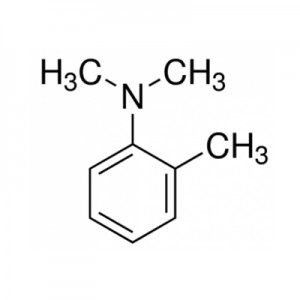

| Ifomula yeMolekyuli | C24H38O4 |

| Ubunzima beMolekyuli | 390.3 |

| Indalo | Ulwelo olungenabala olunamafutha, olungenakunyibilika emanzini, inyibilike kwizinyibilikisi ezininzi eziphilayo

ezifana ne-ethanol kunye neoyile yamaminerali. |

| Ubungakanani | 0.9861 (20/20) |

| Indawo yokunyibilika ° c | -55 |

| Indawo yokubilisa ° c | 370 (uxinzelelo lomoya) |

| Isalathiso somgangatho | I-GB11406-89 |

| Iprojekthi ibanga elihle kakhulu | Ibanga lokuqala |

| Ngaphandle | Ulwelo olunamafutha ngaphandle kokungcola okubonakalayo |

| IChroma (iplatinam-cobalt) emva konyango lobushushu | 100 - |

| Umxholo kaEster | Ukufikelela kwi-99.5 99 |

| Ukuxinana (p20) g / m3 | 0.982-0.988 0.982-0.988 |

| I-asidi (ngokwe-phthalic acid)% | 0.01 0.015 |

| Ukunciphisa ukufudumeza | Umlinganiselo we-0.2 0.3 |

| Indawo yeflashsi c | Ngowe-195 192 |

| IChroma (iplatinam-cobalt) emva konyango lobushushu | 100 - |

| Ukuxhathisa kwevolumu. I-CM | "1x10" - |

Iinkcukacha ezikhawulezayo

Indlela yokusonga yokusetyenziswa

1, uhlobo emanzini: Soak yonke workpieces ukuba zihluthwe remover yepeyinti kangangemizuzu eli-1-20, ifilimu ipeyinti nga zonke ziphume, (ixesha processing ezahlukeneyo ngenxa nentlaka ezahlukeneyo), uwukhuphe kwaye usebenzise amanzi uxinzelelo oluphezulu ukuze unkqonkqoze ishiye intsalela yeetshiphusi zeetshiphusi ezinamathele kumphezulu womsebenzi, (ikwafumaneka ngokhuni, uqalo lokususa uqalo ukususa ulusu lwepeyinti), yihlambe ngamanzi. Rhoqo ucoca intsalela yepeyinti esuswe kunye nomgubo weplastiki; Xa ungasetyenziswa, gubungela isitya; Ukuba ufuna ukucubungula ngokukhawuleza, unokukrwela umphezulu wengubo yokusebenza, ngqo kwi-matrix; Sebenzisa ubushushu mabungagqithi kuma-40 ℃.

2. Uhlobo lwebrashi: Indawo yokusebenza kufuneka ibekwe iflethi ukulungiselela ukwakhiwa. Kwimisebenzi emikhulu yokusebenza, ibrashi okanye umsonto womqhaphu ungasetyenziselwa ukupeyinta isiqwengana sepeyinti kumalungu aza kuhluthwa, kwimisebenzi eshinyeneyo, inokupeyintwa ngokuphindaphindiweyo amaxesha ama-2-3 de kube ifilimu yepeyinti iwe, emva kokuba inkqubo yokucoca ifana uhlobo lokuntywiliselwa.

Imiyalelo esongiweyo yokusetyenziswa

Le mveliso inokufakwa okanye ifakwe ibrashi. Ingasetyenziswa ngokuthe ngqo, ugalele ipeyinti yokuhombisa kwisitya esine-asidi (isamente okanye isinyithi ebekwe ngebhodi ye-10mm ye-PE), emva koko yongeza inani elifanelekileyo lamanzi acocekileyo ukugubungela umphezulu wepeyinti yokutywina amanzi ukunqanda umphunga. Le mveliso igcinwe kakuhle kwiibhotile zeglasi, i-enamelware, iingqayi zeekheram, izikhongozeli zentsimbi ezingenazingcingo, ukugcinwa komoya okungagqitywanga ixesha elide, imigqomo ye-polyethylene engqindilili okanye imigqomo ye-polypropylene ingagcinwa ixesha elifutshane.

Ipeyinti yokurhola iarhente, iarhente yokuhambisa izixhobo ngombane

Iimpawu Product.

Ipeyinti yokuqhekeza: ukusebenza ngokulula, ukusebenza ngokukuko okuphezulu, akukho mhlwa kwisiseko sentsimbi, isiphumo esihle kwiintlobo ezahlukeneyo zokususa ifilimu yepeyinti; kwaye le mveliso ayiqulathanga i-wax, kulula ukuyicoca indawo yentsimbi emva kokupeyinta, ayichaphazeli ukupeyinta kwakhona.

Umda osebenzayo.

Imveliso isetyenziswa ngokubanzi ukususa zonke iintlobo zeepeyinti, ngakumbi ifanele ipeyinti ye-alkyd eyomileyo, ipeyinti ye-electrophoresis, ipeyinti eyomileyo ye-amino, ipeyinti ye-nitro, ipeyinti ye-acrylic kunye nepeyinti yomgubo kunye neqondo lobushushu eliphantsi lokunyanga ipeyinti yamacandelo amabini.

Izinto eziluncedo zokuphelisa ipeyinti.

1.Umgangatho ozinzileyo, ongazinzanga, onobungqongileyo kwaye osebenzayo.

2. Ubunzima beemolekyuli buhlala bufana ngaphambi nasemva kokususwa kwepeyinti, ngaphandle kokonakalisa i-substrate.

3. ukwandisa kakhulu imveliso. Ukulungele ukuqhubeka, imveliso enkulu ezenzekelayo, ngaloo ndlela kuncitshiswe iindleko zabasebenzi.

Inkqubo yokuqhawula ipeyinti ilula kwaye ilula, igqitywe ngenyathelo elinye, ayiyityhefu.

Imiyalelo yokusebenzisa

Ipeyinti yokuqhekeza inokubrashwa okanye ifakwe

Indlela yokuhluba ipeyinti kumphezulu wentsimbi: tshiza imveliso kumphezulu womaleko oza kuhluthwa, ifilimu yakudala iyathamba, ishwabane, idume kwaye emva koko iwe kwimizuzu embalwa, emva koko uhlambe ukungcola ngamanzi uyiyeke yomile; Isambatho esityebileyo, sinokuphinda sisetyenziswe kube kanye, emva koko uhlambe ngamanzi, okanye usebenzise isandpaper kunye ne-spatula ukususa intsalela yendawo. Umphezulu wesinyithi wokwehlisa ipeyinti kufuneka wenziwe emva konyango lomphezulu kwaye emva koko ulusebenzise.

Indlela yokuqhekeza ipeyinti yomphezulu womthi: Ukupeyinta umphezulu womthi, tshiza imveliso kwinxalenye eza kuhluthwa iphindaphindwe ide ifilimu yepeyinti ithambe, emva koko usebenzise ispatula ukususa ifilimu ethanjisiweyo ethambileyo. Kwibhodi ehluthwe ipeyinti, sebenzisa i-sandpaper efanelekileyo ukuyipolisha, susa intsalela ebhodini, emva koko uqhubeke nomsebenzi olandelayo.

Isilumkiso.

1, Xa usebenzisa, nxiba ukhuseleko iliso kunye iiglavu zokuzikhusela, kwaye ulungise isitya samanzi ukuqinisekisa ukuba okusingqongileyo umoya.

2. Vula isiciko sangaphandle ngokucothayo, uze ubambe ngononophelo isiciko sangaphakathi ngepleyisi ukukhupha umoya kancinci.

3, Sebenzisa izikhongozeli zeplastiki okanye zentsimbi kwi-stripper.

4, Ukuba imveliso iyatshiza emehlweni okanye kulusu, gungxula ngamanzi kwangoko.

Ukugcinwa kunye nokuthuthwa: Xa kugcinwa imveliso, kufuneka igcinwe ivaliwe, ipholile kwaye inomoya ukuthintela ilanga ngqo kude nomthombo wobushushu. Kufuneka ihanjiswe ngokungqinelana nemigaqo efanelekileyo yokuthintela ukubakho kwemvula kunye nelanga.

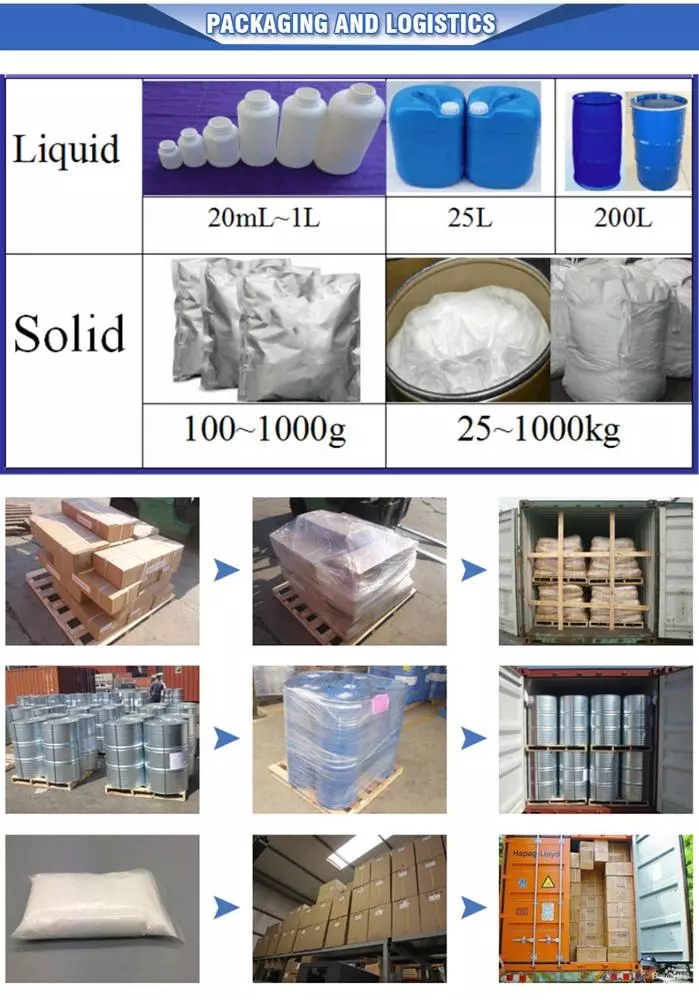

Inkcazo yephakheji.

Ukupakisha: Ubunzima bomnatha: 30kg / umphanda, 200kg / umphanda.

2. Ukugcinwa: kutywinwe kwaye kugcinwe kwindawo epholileyo, eyomileyo kunye nomoya, indawo yokuhlala: Iminyaka emi-2 ukusukela kumhla wokuveliswa.

Indlela yokusonga yokusetyenziswa

1, uhlobo emanzini: Soak yonke workpieces ukuba zihluthwe remover yepeyinti kangangemizuzu eli-1-20, ifilimu ipeyinti nga zonke ziphume, (ixesha processing ezahlukeneyo ngenxa nentlaka ezahlukeneyo), uwukhuphe kwaye usebenzise amanzi uxinzelelo oluphezulu ukuze unkqonkqoze ishiye intsalela yeetshiphusi zeetshiphusi ezinamathele kumphezulu womsebenzi, (ikwafumaneka ngokhuni, uqalo lokususa uqalo ukususa ulusu lwepeyinti), yihlambe ngamanzi. Rhoqo ucoca intsalela yepeyinti esuswe kunye nomgubo weplastiki; Xa ungasetyenziswa, gubungela isitya; Ukuba ufuna ukucubungula ngokukhawuleza, unokukrwela umphezulu wengubo yokusebenza, ngqo kwi-matrix; Sebenzisa ubushushu mabungagqithi kuma-40 ℃.

2. Uhlobo lwebrashi: Indawo yokusebenza kufuneka ibekwe iflethi ukulungiselela ukwakhiwa. Kwimisebenzi emikhulu yokusebenza, ibrashi okanye umsonto womqhaphu ungasetyenziselwa ukupeyinta isiqwengana sepeyinti kumalungu aza kuhluthwa, kwimisebenzi eshinyeneyo, inokupeyintwa ngokuphindaphindiweyo amaxesha ama-2-3 de kube ifilimu yepeyinti iwe, emva kokuba inkqubo yokucoca ifana uhlobo lokuntywiliselwa.

Inowuthi yokusonga

1, Xa le mveliso isetyenziselwa izinto ezingaziwayo, nceda uvavanye indawo encinci kuqala kwaye emva kokuba kungekho mpendulo ifunyenweyo.

Ngenxa yokuba imveliso inokuvelisa isixa esithile segesi emgqonyeni, ke ngoko, ngaphambi kokuvula isiciko, nceda sukukhomba ubuso bakho emlonyeni webhokisi yokupakisha ukunqanda irhasi engxamile ebusweni bakho. Xa uvula isiciko, nceda usikhulule kancinane kwaye uyeke igesi ihambe kancinci ngokwayo. Nceda unxibe iiglavu zelatex kwaye uphakamise umoya ukunqanda ukudibana nolusu, ukuba luyatshiza emehlweni, gungxula ngamanzi ngokukhawuleza kwaye ubonane nogqirha.

3, Emva kokususa umboniso wepeyinti ngale mveliso, nceda ususe intsalela xa ufafaza.

4, Package: 25kg / 180kg igubu zeplastiki. Kufuneka ihanjiswe njengekhemikhali yolwelo ngokubanzi, itywinwe kwaye igcinwe kwindawo epholileyo kwaye enomoya, kwaye igcinwe kubushushu obungaphantsi kwe -10 ℃ ebusika, kunye neshelf life yonyaka omnye.

Qaphela: Izixhobo zeHardware zokutshiza ngepeyinti okanye ukutshiza iplastiki ngaphambi konyango lwe-phosphating.

Ukuwa kuHlela ukuhlela lo mhlathi wepeyinti oqhelekileyo

Ipeyinti yepeyinti, Ipeyinti yesiqhoboshi, Ipeyinti yesixhobo, Ipeyinti yesixhobo, Ipeyinti yesixhobo, Ipeyinti yepeyinti, Strip Paint Stripper, Stripper Paint Stripper, Ukupeyinta iPeyinti, Stripper Paint Stripper, Umqhubi

Iindidi zepeyinti yokupeyinta

1) Ipeyinti yealkali epeyintiweyo

Kwelinye icala, ialkali is saponify amaqela athile ngepeyinti kwaye inyibilika emanzini; Kwelinye icala, umphunga oshushu upheka ifilimu yepeyinti, ebangela ukuba iphelelwe ngamandla kwaye inciphise ukunamathela kwayo kwisinyithi, okuthi, kunye nefuthe lokungena, ukungena kunye nokuhlangana, ekugqibeleni kubangele ukugquma okudala kuphele.

2) Acid ipeyinti yokuhambisa

I-acid yepeyinti yokupeyinta sisixhobo sokupeyinta esenziwe ngee-asidi ezomeleleyo ezinje nge-sulfuric acid egxile, i-hydrochloric acid, i-phosphoric acid kunye ne-nitric acid. Ngenxa yokuba i-hydrochloric acid kunye ne-nitric acid igxile ngokulula kwaye ivelise inkungu yeasidi, kwaye ineziphumo ezonakalisayo kwisiseko sesinyithi, kwaye i-phosphoric acid egxile ithatha ixesha elide ukuba iphele ipeyinti kwaye inefuthe elibi kwi-substrate, ke, ezi asidi zintathu zingasentla kunqabile isetyenziselwa ukuphelisa ipeyinti. I-asidi ye-sulfuric acid kunye ne-aluminium, isinyithi kunye nezinye izinto ezenziwayo zesinyithi, ngoko ke umhlwa wentsimbi mncinci kakhulu, kwaye kwangaxeshanye une-dehydration eyomeleleyo, i-carbonization kunye ne-sulfonation yemicimbi ye-organic kwaye iyenze inyibilike emanzini. isetyenziswe kwipeyinti yokupeyinta iasidi.

3) Ipeyinti yesiqwengana sepeyinti esiqhelekileyo

Isixhobo sokupeyinta esiqhelekileyo sesinyibilikisi senziwe ngomxube wesinyibilikisi esiqhelekileyo kunye neparafini, enje nge-T-1, T-2, T-3 stripper; I-T-1 yepeyinti yokupeyinta yenziwe nge-acetate ye-ethyl, i-acetone, i-ethanol, i-benzene, iparafini; I-T-2 yenziwe nge-acetate ye-ethyl, i-acetone, i-methanol, i-benzene kunye nezinye izinyibilikisi kunye neparafini; I-T-3 yenziwe ngemethylene chloride, iplexiglass, iglasi yeplexi kunye nezinye izinyibilikisi ze-organic kunye neparafini; I-T-2 yenziwe nge-acetate ye-ethyl, i-acetone, i-methanol, i-benzene kunye nezinye izinyibilikisi kunye neparafini. I-Ethanol, iparafini wax, njl njl. Zixutywe, ityhefu esezantsi, ifuthe elifanelekileyo lokuthambisa ipeyinti. Banempembelelo yokupeyinta ipeyinti ye-alkyd, ipeyinti ye-nitro, ipeyinti ye-acrylic kunye nepeyinti ye-perchlorethylene. Nangona kunjalo, isinyibilikisi sezinto eziphilayo kolu hlobo lwepeyinti yokuqhekeza ayizukutsha, inokutsha kwaye inetyhefu, ke kufuneka ifakwe endaweni enomoya owaneleyo.

4) I-hydrocarbon solvent ipeyinti yokuhambisa ipeyinti

I-hydrocarbon ye-solvent paint solver isombulula ingxaki yokupeyinta i-epoxy kunye ne-polyurethane, kulula ukuyisebenzisa, ukusebenza ngokukuko kunye nokungonakali kakhulu kwizinyithi. Ubukhulu becala iqulethe izinyibilikisi (imichilo yepeyinti yesiko ubukhulu becala isebenzisa i-methylene chloride njengesinyibilikisi se-organic, ngelixa imichilo yepeyinti yanamhlanje ihlala isebenzisa izinyibilikisi eziphezulu ezinje nge-dimethylaniline, i-dimethyl sulfoxide, i-propylene carbonate kunye ne-N-methyl pyrrolidone, edityaniswe neziselo ezinxilisayo kunye nezinyibilikisi ezinevumba elimnandi, okanye zidityaniswe ne-hydrophilic alkaline okanye inkqubo ye-asidi), izinto ezinyibilikayo (ezinje nge-methanol, i-ethanol kunye ne-isopropyl alcohol, njl. njl.) Izinto ezenziwayo (ezinjenge phenol, formic acid okanye i-ethanolamine, njlnjl.), thickeners (ezifana ne-polyvinyl alcohol, methyl cellulose , i-ethyl cellulose kunye ne-silica enefutha, njl. njl.), Izinto ezinokuthintela ukungasebenzi (ezinje nge-parafini wax, i-ping ping, njl. njl.), ii-surfactants (ezinje nge-OP-10, OP-7 kunye ne-sodium alkyl benzene sulfonate, njl.), ii-corrosion inhibitors, iiarhente zokungena, iiarhente zokumanzisa kunye neearhente ze-thixotropic.

5) Ipeyinti esekwe emanzini

E-China, abaphengululi baphumelele ngempumelelo ipeyinti esekwe emanzini esebenzisa i-benzyl alcohol endaweni ye-dichloromethane njengeyona solvent iphambili. Ngaphandle kotywala be-benzyl, ikwabandakanya ukuqina kwe-arhente, i-inhibitor eguqukayo, isilumkisi kunye ne-surfactant. Ubume bayo obuyisiseko (umyinge wevolumu): i-20% -40% yecandelo lesinyibilikisi kunye ne-40% -60% yecandelo elise-asidi elinamanzi elinomatshini oshukumayo. Xa kuthelekiswa nedichloromethane yokupeyinta yemveli, inetyhefu encinci kunye nesantya esifanayo sokususwa kwepeyinti. Ingasusa ipeyinti ye-epoxy, i-epoxy zinc primer etyheli, ngakumbi ipeyinti yokukhusela inqwelomoya inefuthe elihle lokupeyinta.

Wisa ukuhlela lo mhlathi izinto eziqhelekileyo

1) Isinyibilikisi sokuqala

Isinyibilikisi esingundoqo singanyibilikisa ifilimu yokupeyinta ngokungena kweemolekyuli kunye nokudumba, okunokutshabalalisa ukunamathela kwifilimu yepeyinti kwi-substrate kunye nolwakhiwo lomhlaba wefilimu yepeyinti, ke i-benzene, i-hydrocarbon, i-ketone kunye ne-ether zihlala zisetyenziswa njengezinyibilikisi eziphambili , kunye nehydrocarbon yeyona ilungileyo. Ezona nyibilikisi eziphambili yi-benzene, iihydrocarbon, iietoni kunye nee ether, kwaye iihydrocarbons zezona zibalaseleyo. Ipeyinti yesinyibilikisi enetyhefu esezantsi engenayo i-methylene chloride ikakhulu ine-ketone (pyrrolidone), i-ester (methyl benzoate) kunye ne-ether yotywala (i-ethylene glycol monobutyl ether), njalo njalo. I-Ethylene glycol ether ilungile kwi-resin yepolymer. I-Ethylene glycol ether ine-solubility eyomeleleyo kwi-resin yepolymer, ukungena kakuhle, indawo yokubilisa ephezulu, ixabiso elithengiweyo, kunye ne-surfactant efanelekileyo, ngoko iyasebenza kuphando lokuyisebenzisa njengeyona nyibilikisi iphambili yokulungisa ipeyinti (okanye iarhente yokucoca) ngesiphumo esihle kunye nemisebenzi emininzi.

Imolekyuli ye-benzaldehyde incinci, kwaye ukungena kwayo kwityathanga le-macromolecule yomelele, kwaye ukunyibilika kwayo kwimicimbi ye-polar yomelele nayo yomelele kakhulu, eya kwenza ukuba ii-macromolecule zonyuke ngevolumu kwaye zivelise uxinzelelo. Ityhefu esezantsi kunye nokwehla kwento yokupeyinta okulungiswe nge-benzaldehyde njengoko isinyibilikisi inokuyisusa ngokufanelekileyo i-epoxy powder enxibe umphezulu wesinyithi kubushushu begumbi, kwaye ikwalungele nokususwa kwepeyinti yokukhusela inqwelomoya. Ukusebenza kwale stripper yepeyinti kuthelekiswa naleyo yemichiza yemizobo yepeyinti yemichiza (uhlobo lwe-methylene chloride kunye nohlobo olushushu lwealkali), kodwa kuncinci kakhulu ekubonakaliseni iziqwenga zentsimbi.

I-Limonene yinto elungileyo yabaphandi bepeyinti kwimbono ehlaziyekayo. Sisinyibilikisi sehydrocarbon esikhutshwe kwixolo leorenji, iteline yomgubo kunye neelitron. Isinyibilikisi esihle segrisi, i-wax kunye nentlaka. Inendawo yokubilisa ephezulu kunye nenqaku lokutshaya kwaye kukhuselekile ukusetyenziswa. Izinyibilikisi ze-Ester zinokusetyenziswa njengempahla ekrwada yokupeyinta. Izinyibilikisi ze-Ester zibonakaliswa yityhefu esezantsi, ivumba elimnandi kunye nokunganyibiliki emanzini, kwaye zisetyenziswa njengezinyibilikisi zezinto eziphilayo ezinamafutha. I-Methyl benzoate ngummeli we-ester solvents, kwaye abaphengululi abaninzi banethemba lokuyisebenzisa kwipeyinti yokupeyinta.

2) Isinyibilikisi sokubambisana

I-co-solvent inokunyusa ukuchithwa kwe-methyl cellulose, iphucule i-viscosity kunye nokuzinza kwemveliso, kwaye isebenzisane ne-molecule eziphambili ze-solvent ukungena kwifilimu yepeyinti, ukunciphisa ukunamathela phakathi kwefilimu yepeyinti kunye ne-substrate, ukwenzela ukuba ukhawuleze ukunyusa izinga lokuphungula ipeyinti. Inokunciphisa umyinge wesinyibilikisi esingundoqo kunye nokunciphisa iindleko. Utywala, ii-ether kunye nee-esters zihlala zisetyenziswa njenge-co-solvents.

3) Umnyusi

Umnyusi wenani lezinyibilikisi ze-nucleophilic, ngakumbi ii-asidi ze-organic, ii-phenols kunye nee-amine, kubandakanya i-formic acid, i-acetic acid kunye ne-phenol. Isebenza ngokutshabalalisa amatyathanga e-macromolecular, ukukhawulezisa ukungena kunye nokudumba kwengubo. I-acid ye-Organic iqulethe iqela elifanayo elisebenzayo njengokwakhiwa kwefilimu yepeyinti- OH, inokunxibelelana nenkqubo yokuqhekeza yeoksijini, initrogen kunye nezinye iiathom ze-polar, iphakamisa inkqubo yenxalenye yeendawo ezinqamlezileyo zomzimba, ngaloo ndlela inyusa ipeyinti izinga lokusasazeka kwendalo, ukuphucula ukudumba kwefilimu kunye nokukwazi ukushwabana. Kwangelo xesha, ii-asidi ze-organic zinokunyanzela i-hydrolysis ye-ester bond, i-ether bond ye-polymer kwaye iyenze yaphule iqhina, okukhokelela ekulahlekelweni kukomelela kunye ne-brittle substrates emva kokupeyinta.

Amanzi achongiweyo sisinyibilikisi esisigxina se-dielectric rhoqo (ε = 80120 ngo-20 ℃). Xa umphezulu oza kuhluthwa yi-polar, njenge-polyurethane, i-dielectric solvent solvent ephezulu inefuthe elihle lokwahlula umphezulu we-electrostatic, ukuze ezinye izinyibilikisi zingene kwii-pores phakathi kwengubo kunye ne-substrate.

Iperoksayidi yeHydrogen ibola kwiindawo ezininzi zesinyithi, evelisa ioksijini, ihydrogen kunye nefomathi yeoksijini yeatom. Ioksijini ibangela ukuba uthambeko lokhuselo oluthambileyo luqengqeleke, ivumela ipeyinti entsha yokungena ukuba ingene phakathi kwesinyithi kunye nokwaleka, ngaloo ndlela kukhawulezisa inkqubo yokuhluba. Ii-Acids ziyinxalenye ephambili kwimixube yepeyinti, kwaye umsebenzi wabo kukugcina i-pH yepeyinti yokupeyinta ngo-210-510 ukuze isabele ngamaqela e-amine simahla kwimpahla ezinjenge-polyurethane. Iasidi esetyenzisiweyo inokunyibilika i-asidi eqinileyo, i-acid engamanzi, i-organic acid okanye i-acid engaphiliyo. Njengokuba i-inorganic acid isenokwenzeka ekuveliseni ukubola kwesinyithi, ke kungcono ukusebenzisa ifomula ye-RCOOH ngokubanzi, ubunzima beemolekyuli ezingaphantsi kwe-1,000 ze-organic acid, ezinjenge-formic acid, i-acetic acid, i-propionic acid, i-butyric acid, i-valeric acid, i-hydroxyacetic acid, hydroxybutyric acid, lactic acid, citric acid kunye nezinye iihydroxy acid kunye nemixube yazo.

4) Ukuqinisa

Ukuba isipeyinti sokupeyinta sisetyenziselwa izinto ezinkulu ezakhiweyo ezifuna ukubambelela kumphezulu ukuze zisabele, kuyafuneka ukongeza ii-thickeners ezinjengee-polymers ezinyibilikiswa ngamanzi ezinjenge-cellulose, i-polyethylene glycol, njl., Okanye iityuwa ezingaphiliyo ezinjenge-sodium chloride , i-potassium chloride, i-sodium sulfate, kunye ne-magnesium chloride. Kufuneka iqatshelwe into yokuba iityuwa ezingaphiliyo zilungelelanisa i-viscosity ziya kunyuka ngedosi yazo, ngaphaya koluhlu, i-viscosity iyancitshiswa endaweni yoko, kunye nokukhetha okungafanelekanga kunokuba nefuthe kwezinye izinto.

I-Polyvinyl yotywala yipolymer e-soluble enamanzi, enokunyibilika kwamanzi, ukwenza ifilimu, ukubambelela kunye ne-emulsification, kodwa zimbalwa iikhompawundi eziphilayo ezinokuyinyibilikisa, iikhompawundi zepolyol ezinje nge-glycerol, i-ethylene glycol kunye nobunzima beemolekyuli eziphantsi zepolyethylene glycol, amide, triethanolamine ityuwa, i-dimethyl sulfoxide, njl., kwezi nyibilikisi zingasentla, nyibilikisa inani elincinci le-polyvinyl yotywala nayo ifuna ukufudunyezwa. Isisombululo se-Polyvinyl yotywala esine-benzyl yotywala kunye nomxube we-acid wokungqinelana okungalunganga, ukugcekwa ngokulula, kwaye kwangaxeshanye ne-methyl cellulose, i-hydroxyethyl cellulose solubility yamahlwempu, kodwa i-carboxy methyl cellulose solubility ingcono.

Polyacrylamide yi yomgama Polymer-enyibilikayo amanzi, yona kunye neziphumo zayo zingasetyenziswa njenge flocculants, thickeners, iphepha enhancers kunye retarders, njl .. Njengoko polyacrylamide chain molekyuli iqulathe iqela amide, oko luphawulwa hydrophilicity eliphezulu, kodwa ayinyibiliki kakhulu izisombululo ze-organic, ezinje nge-methanol, i-ethanol, i-acetone, i-ether, ii-hydrocarbon ze-aliphatic kunye neehydrocarbon ezinamakha. Isisombululo seMethyl cellulose elulwelo kuhlobo lwe-benzyl yotywala ye-asidi ezinzile, kwaye izinto ezahlukeneyo ezinokunyibilika emanzini zinokudityaniswa okuhle. Isixa se-viscosity kuxhomekeke kwiimfuno zokwakha, kodwa isiphumo sokuqina asilingani ngokuthe ngqo nesixa, kunye nokunyuka kwenani lokongezwa, isisombululo esinamanzi ngokuthe ngcembe sinciphisa ubushushu be-gelation. Uhlobo lweBenzaldehyde alunakonyuswa ngokudibanisa i-methyl cellulose ukufezekisa isiphumo se-viscosity.

5) Umhlwa Inhibitor

Ukuthintela ukubola kwe-substrate (ngakumbi i-magnesium kunye ne-aluminium), isixa esithile se-corrosion inhibitor kufuneka songezwe. Ukubola yingxaki engenakuhoywa kwinkqubo yokwenyani yemveliso, kwaye izinto eziphathwe ngepeyinti kufuneka zihlanjwe kwaye zomiswe ngamanzi okanye zihlanjwe nge-rosin nepetroli ngexesha elifanelekileyo ukuqinisekisa ukuba isinyithi kunye nezinye izinto azonakalisi.

6) Inhibitors eziguqukayo

Ngokubanzi, izinto ezinokungena ngokulula kulula ukuzinyusa, ke ukuze kuthintelwe i-volatilization yeemolekyuli eziphambili zesinyibilikisi, isixa esithile se-volatilization inhibitor kufuneka songezwe kwipeyinti yokupeyinta ukunciphisa i-volatilization yeemolekyuli zesinyibilikisi kwinkqubo yemveliso , ukuthuthwa, ukugcinwa kunye nokusetyenziswa. Xa ipeyinti yokupeyinta enephalafini ifakwa kumphezulu wepeyinti, kuya kwenziwa umaleko omncinci weparafini kumphezulu, ukuze ezona molekyuli ziphambili zibe nexesha elaneleyo lokuhlala zingene kwifilimu yepeyinti ukuze isuswe, yiyo loo nto ukuphucula umphumo wokususa ipeyinti. I-parafini wax eqinileyo yodwa ihlala ibangela ukusasazeka okungafanelekanga, kwaye inani elincinci leparafini liyakuhlala ngaphezulu emva kokususwa kwepeyinti, okuya kuchaphazela ukuphinda kutshizwe. Ukuba kukho imfuneko, yongeza i-emulsifier ukunciphisa uxinzelelo lomhlaba ukuze i-wax yeparafini kunye neparafini engamanzi ikwazi ukusasazeka kakuhle kunye nokugcinwa kozinzo kuphuculwe.

7) Umtsalane

Ukongezwa kwama-surfactants, anjengee-amphoteric surfactants (umz., Imidazoline) okanye ethoxynonylphenol, inokunceda ukuphucula uzinzo lokugcina ipeyinti yokurhola kunye nokwenza lula ukucoca ipeyinti ngamanzi. Kwangelo xesha, ukusetyenziswa kweemolekyuli ezisebenza ngokusebenza kunye zombini lipophilic kunye nehydrophilic ezimbini ezichasene nepropathiant zinokuchaphazela ukusebenza kwe-solubilization; Ukusetyenziswa kweqela elisebenzayo le-colloidal, ukuze ukunyibilika kwezinto ezininzi kwisinyibilikisi kunyuke kakhulu. Izinto eziqhelekileyo ezisetyenziswayo zisebenza njengepropylene glycol, isodiyamethilini kunye ne-sodium xylenesulfonate.